In this blog post, we will explore a fundamental aspect of stainless steel name plates: the thickness of the periodic layers. The thickness of stainless steel nameplates is an important detail across many industries, contributing to longevity, functionality, and visual appeal. Our goal is to explore the influential factors, how to measure them, choose the right thickness for a desired application, and the common measurements used. No matter what type of application you want to achieve: for industrial, signage, or decorative purposes, the knowledge of the differences of the stainless steel name badge thickness is going to help you make the right decision and achieve your target result.

Steel name plate thickness is the critical size parameter that affects its ultimate strength, reliability as well as how it works and performs. It is this section that indicates the amount of material, which is the metal from the stainless steel plaque, used in forming this plate.

A thicker stainless steel label normally has greater strength and rigidity to withstand bending or warping, thus desired for applications that require resistance to bend and long-lasting performance. On the other hand, thinner stainless steel signage plates shall be cheaper and much lighter while some of them will only have limited durability depending on the environment they are placed in.

Determination of the thickness of the nameplate from stainless steel is key in finding the product that suits individual applications. On the other hand, the thickness of the steel identification plate could be for the industrial machines, the outdoor signages, or, the decorator, and it has to match the requirements of the usage.

Understanding that stainless steel metal identification plate, thickness matters, businesses and individuals will be able to make an educated choice rather than a random one when purchasing nameplates for their projects, and thus embossing nameplates that are durable economically viable, and inevitable.

Factors Influencing Thickness:

Several factors influence the thickness of stainless steel nameplates, each playing a significant role in determining the optimal dimension for specific applications:

Material Grade: Although various grades of stainless steel have varied features and qualities, they all share the same characteristics. The choice of the material grade will affect the thickness of the nameplate which depends on the properties of the material such as corrosion resistance, strength, and durability.

Application Requirements: A considerable factor in deciding the thickness of a name plate made from stainless steel. Thus, processes, such as the engraving of nameplates on heavy-duty industrial machines, indicate the usage of thicker material to cope with the mechanical stress and harmful work environment. However, the specifications for decorative nameplates mostly relate to their aesthetic features rather than the thickness such as the design and the surface finish of the nameplate.

Environmental Conditions: Regarding the installation site, one may modify the thickness requirements of the nameplate. Exposed to aggressive chemicals, extremes of temperature, moisture, and self-radiation may require plating with stainless steel of greater thickness to ensure proper operation over a long-lasting period.

Regulatory Standards: Specific industries and applications may be the standards and requirements of the terminals of their own types or with the compliance resulting from them. Adherence to the aforementioned regulations is fundamental to secure the normal operation, functionality, and compliance of the nameplate with the existing norms.

Budget Constraints: Over and above cost considerations, the steel identification plate thickness may likewise be the deciding characteristic. Thicker materials take longer to produce, therefore usually at a higher cost, which means the engineers have to take into account the effectiveness and the budget when designing an airplane.

A thoughtful deliberation of the key factors which include the content, aesthetics, thickness including performance and functional requirements of application shall help manufacturers, designers, and end-users select the proper thickness of stainless steel name board for their intended purpose.

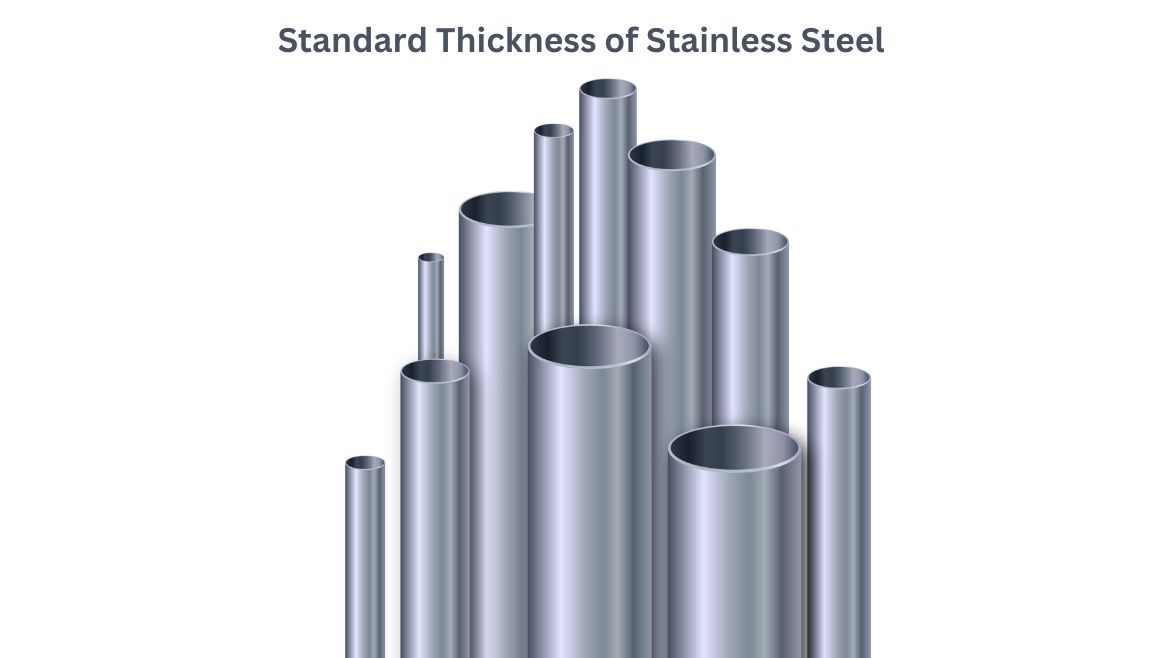

Standard Thicknesses for Stainless Steel Nameplates:

Stainless steel nameplates come in many sizes to fill up the range of commonly used thicknesses that are normally noted in inches or millimeters. Thickness is determined by different factors like modes of use, climatic factors, and preferences of aesthetics. Here are some common standard thicknesses for stainless steel identification tags:

• 0.02 inches (0.5 mm): This select higher gauge is usually preferred for large-size applications where rigidity and lightweight are necessary, such as in indoor billboards and decorative nameplates.

• 0.04 inches (1 mm): The width of the present cardstock is slightly larger than 0.02 inches, giving you added strength against bending or warping. It allows all kinds, for example, equipment signboards and tags.

• 0.06 inches (1.5 mm): This model has an intermediate thickness that makes it durable and it is also flexible to suit both indoor and outdoor exercises. It's frequently employed for labeling machinery, control, and industrial panels, as well as equipment signage.

• 0.08 inches (2 mm): The thicker grade gives better strength and torsion control for heavy industrial work and outdoor use synchronizing with harsh weathering conditions.

• 0.12 inches (3 mm) and above: These heavier-gauge strands are applied in the case of the most robust designs aimed to provide maximum resistance to mechanical stress and environmental factors. Often they are an indispensable element of marine, aerospace, and rail transport systems.

Deciding on the thickness of stainless steel custom is partly a matter of the demands for resilience, overall visibility, and budgeting in the application area. Subsequently, to avoid ownership of standards and providing messed up functionality, manufacturers and users need to pay sufficient attention to the check of the thicknesses.

Measuring Thickness:

The most accurate thickness measurement of a stainless steel nameplate is a critical component of ensuring that, certain specification is achieved and that performance is guaranteed. Several methods can be employed to measure thickness effectively:

Using Calipers: Digital or analog calipers are most frequently used to measure the width of such a steel nameplate. Just spread the teeth of the calipers around the nameplate and bring them together lightly to get an exact measurement.

Micrometer Measurement: To get higher accuracy, the micrometer can be used to raise the name plate size. This device has such a small scale that is proving very useful because it can measure the exact dimensions of thin materials that are in micrometers or millimeters.

Gauge Thickness: Stainless steel nameplate thickness can be measured not only with age thickness standard. Such standards are a supply of wires or plates with constant thickness configured in a series with which the thickness of nameplates can be calculated very fast and accurately.

When incorporating the measurement of the thickness of a stainless-steel nameplate, it is crucial to take into account that the measurement of the thickness is done at multiple points across the surface in order to keep in mind all the irregularities. Furthermore, several times you must measure to acquire a range of precise and error-free values.

By using these measurement techniques manufacturers, QC inspectors, and end-users will be able to check out the stainless steel nameplates for meeting the required thickness specs and perform their tasks at their best in the applications they are expected to be used in.

The thickness of the nameplate from stainless steel has to be understood as it is important in making a selection of the product in accordance with your needs. By taking materials into account grade, needs, environmental conditions, and budget play a very important role in this process, producers and end consumers can select the thickness of their nameplates based on the specifications of different projects.

Industrial grade stainless steel nameplates come in different standard thicknesses which can be used for various purposes receiving desired performance, whether it is signage application for light industrial use, or industrial equipment labeling for heavy-duty use. Hooke's Law dictates that the stiffness of a material is proportional to the thickness of a nameplate in the general range of linear deformations, and this allows us to meet the specifications and performance standards.

The conclusion would be that the thickness of stainless steel name plates has an appropriate thickness for each application contributing toward their fine performance, long-life, and success. Stainless steel engraved plates have different uses varying from mass branding, and identification to the informative function. However, whatever the use is, their thickness must be suitable for the desired requirements.